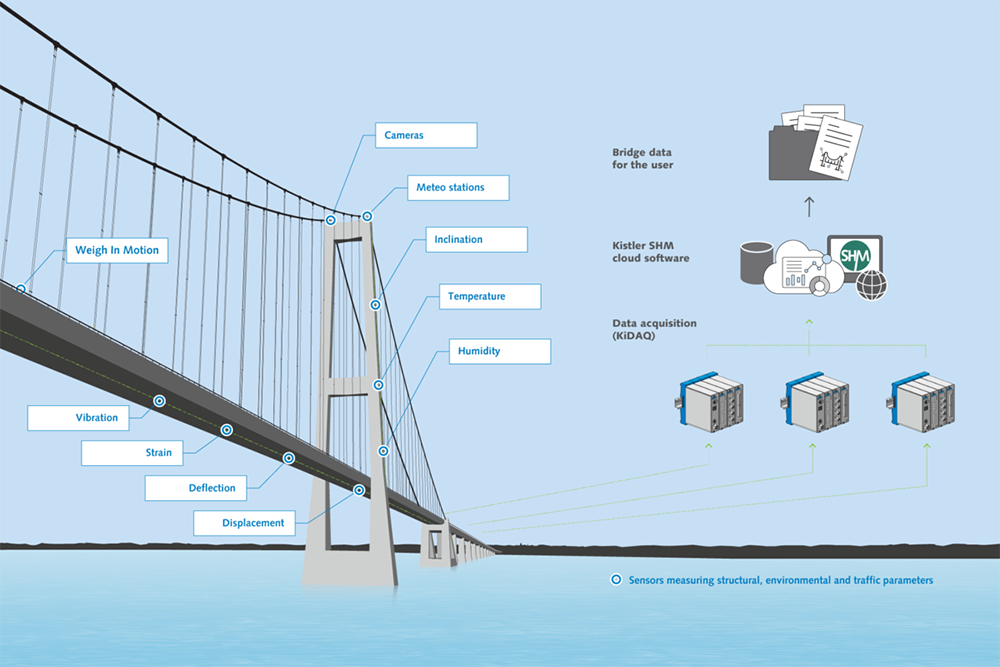

Kistler’s Structural Health Monitoring portfolio system automatically monitors bridge structures on a 24/7 basis. It continuously measures and tracks the actual structural resistance of the bridge and the real traffic load as reported by the integrated WiM system.

In this way, it detects even the smallest structural movements and vibrations as they occur and before they cause more serious damage. Structural engineers and road operators are constantly informed of the relevant data and are notified immediately via notifications and alarms.

The monitoring system provides seamless availability of highly reliable bridge structural data thanks to its acceleration sensors from the K-Beam family. The company’s accelerometers are specifically designed to withstand even the most extreme weather conditions. They operate in temperatures ranging from -55°C to 125°C, have highest temperature stability (variations below 0.01 %/°C), measure highly accurately from 0Hz to 1500Hz and can precisely detect even the smallest vibrations.

In addition to precise sensors, the turnkey solution consists of the KiDAQ data acquisition system and a cloud-based software platform. "This allows users to easily access the data and configure all the equipment remotely," said David Cornu, head of business unit for traffic solutions at Kistler. "This type of system can be used not only to monitor damaged bridges, but also be implemented on new bridges or bridges under reconstruction. Our experts in measurement technology and structural engineering will assist users and operators in designing the optimal monitoring solution."

Stand 01.410