Overseeing the road network of the most populated US state is a mammoth task. To help with the job of counting and classifying vehicles, Californian infrastructure provider Caltrans relied on an old low-cost technology. While the agency was able to make it work, a solution to improve the robustness and data provided by the network was needed. With KiTraffic Statistics (KTS), Kistler provided a system that met both Caltrans’ need for longer-lasting equipment and superior data – while still going easy on the budget.

The road network of the Golden State totals more than 50,000 miles of pavement, a distance that would go round the globe more than twice. Caltrans, a federal organisation that divides the state up into 12 sub-districts, is tasked with keeping this road network safe and reliable.

Its core business is to constantly monitor traffic volume in the respective districts and plan infrastructure accordingly. For years, Caltrans District 3 had relied on equipment that was cost-effective but lagged behind in terms of robustness, longevity and technological performance. The need to update a large number of sites in one project gave Kistler the opportunity to prove its competence along the whole measuring chain.

It started in San José in 2016, when two Caltrans executives - Dean Campbell, senior transportation manager, and electrical engineer Gurdeep Sidhu - met traffic professionals from Kistler at the ITS America meeting and exhibition. Campbell reported issues with his measuring system in the district which includes the Sacramento area. Again and again, the B/L-piezo cables inserted in the road surface would break after a few years’ service. Constant repair work and temporary lane closures were adding additional costs to the programme as well as obstructing the flow of traffic. Also, data management was an issue. US departments of transportation – such as Caltrans – are required to disclose collected data to the public. Caltrans’ existing data management system was meeting the basic requirements but had challenges with data migration into the required systems. On top of that, it provided no real-time traffic information. Lastly, the existing measuring technology was limited to solely counting and classifying vehicles according to their type, e.g. passenger cars, buses or trucks. For Caltrans to effectively plan maintenance, design roads and keep bridges in good condition, additional data on vehicle loads is critical.

Statistics fits the needs

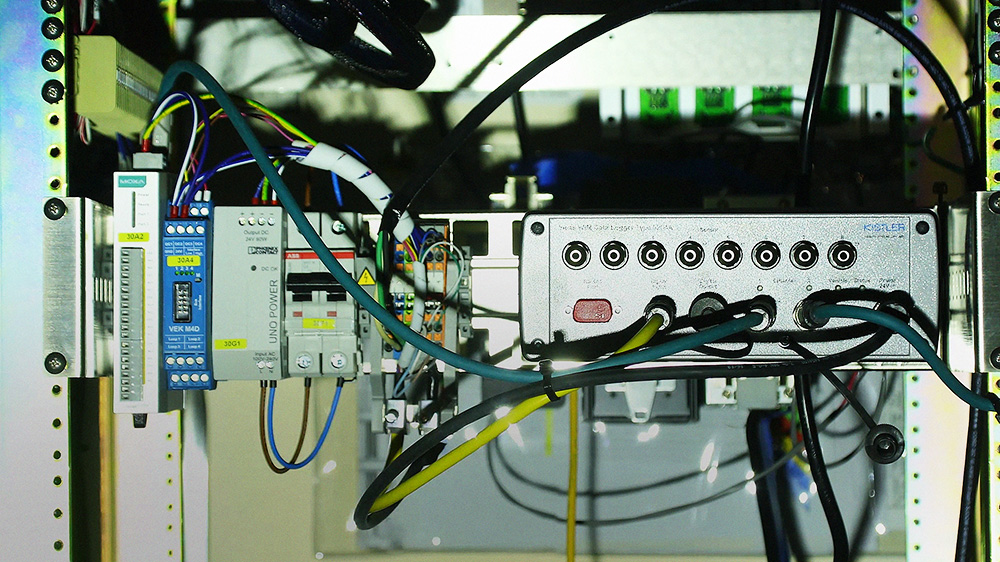

After reviewing Caltrans’ requirements, a Kistler team proposed KiTraffic Statistics (KTS), a solution which features unique Lineas Compact quartz sensors installed into the roads in combination with the Kistler Data Logger installed at the road site and offering a user-friendly interface for comprehensive data evaluation. This type of system is able to register traffic volume, classification and weight by default. As no other Caltrans district had gathered experience with this alternative technology before, Campbell thoroughly assessed the Kistler solution. “The technological superiority of the Kistler solution soon became clear to me. But budget was still a limiting factor,” he recalls. “What tipped the scale in favour of KTS was that it comes at a really affordable price. Also, with less maintenance efforts, it will prove to be the more cost-effective choice in the long run.”

When the deal was signed in 2019, the project started right away – considering the pressing need, there was no time to lose for Caltrans. They ordered sensor equipment for 294 lanes at 64 sites, to be installed within an aggressive time schedule. “Our top priority was to keep lane closure time as short as possible,” Campbell says. To begin with, Kistler ran a thorough inspection of all sites. Jess Helmlinger, regional manager North America – Business Unit traffic solutions at Kistler, explains: “We needed to know about the quality of the roads as cracks and bumps, for example, directly influence the accuracy of the data.” Where the road spec did not match the requirements for installation, Kistler gave recommendations for repositioning the measuring spots. “After all, we were able to exceed the desired confidence interval of +/- 15% gross vehicle weight accuracy at all sites,” Helmlinger adds. “In fact we overachieved with +/- 10% at all sites despite some challenging road conditions.”

Reliable partners key to success

As the project geared up in the spring of 2020, it threatened to be abruptly thwarted by the start of the Covid-19 pandemic. The supply of materials across all industries was delayed, as were many other goods and services. Pacific Excavation (PacEx) was the prime contractor and responsible for delivering the project, including the road installation of the quartz sensors. As Helmlinger remembers: “The project wouldn’t have had the same success if it hadn’t been for their ingenuity, flexibility and efficiency.”

In response to the supply delays, PacEx pre-assembled the automated vehicle classification cabinets in their warehouses instead of on-site. After this preparation, the cabinets were easy to distribute and install in the field. Additionally, PacEx more than doubled the usual size of its installation teams on-site to minimise traffic obstructions and speed up construction schedules. Kistler’s easy-to-handle hardware helped it stay on track as well. “Compared to the former thin piezo cables, the Lineas Compact sensors are straightforward to install. It’s a standardised process,” recalls Jim Paxin, PacEx vice president. Eventually, the project was finished within project time despite the challenges faced in the past two years.

Added value along measuring chain

Kistler says a key strength of KTS is its seamless integration of hardware and software. Every 30 seconds, data from the roads reach the control centre. This gives Caltrans the opportunity to monitor almost in real time – and to identify peak times and typical bottlenecks. Thus, the results provide a solid blueprint for effective road planning. Other stakeholders such as the public and federal authorities now also gain more value from the data: as required, Caltrans offers full transparency with no extra effort. Thanks to the standards-based open architecture of the Kistler software, data can easily be migrated to Caltrans’s proprietary performance-measurement system PeMS. Once into the project, additional opportunities to streamline data and make it more easily available were identified. The Kistler team was able to satisfy this additional request utilising the KTS system.

Throughout the entire project, Kistler says close cooperation with its partners from Caltrans and PacEx has been a key success factor. For the right installation and calibration, Kistler provided more than 100 hours of support as well as training and certification to PacEx workers. “The on-site training has been far superior to anything we have ever dealt with,” insists Peyton Gastelum, project manager at PacEx. Caltrans staff have also been trained on-site and off-site on the complete KTS system. This gives them the flexibility to check on the installation at any time with no added service costs.

The first KTS sites have been in operation for roughly two years now, and, according to Campbell, Caltrans hasn’t experienced any maintenance issues since: “The system is robust and provides valuable data, including the weight of the vehicles. This is going to be highly beneficial for us and the public respectively to better understand traffic flows and manage the infrastructure.” It’s perhaps no surprise that Campbell’s pioneering project has already caught the attention of other districts.