To complement its existing WIM offering, IRD has introduced a system to detect under-inflated and flat tyres at highway speeds.

Tyre inflation pressure has both safety and economic impacts for road users and none more so than with commercial vehicles. An underinflated tyre has decreased directional control, increased risk of catastrophic failure, and negatively impacts tyre life and fuel economy. In June 2014 the USDOT published Large Truck and Bus Crash Facts 2012 in which the Federal Motor Carrier Safety Administration (FMCSA) identifies tyres as the most frequent vehicle-related factor in fatal crashes. Despite industry adoption of onboard technologies such as tyre pressure monitoring systems, flat tyres are a common citation during commercial vehicle inspections. Indeed an American Trucking Association petition to the FMCSA notes that state inspectors issued over 30,000 citations for underinflated tyres within two years.

It would be wrong to deduce that truck operators do not care about the inflation pressure of their tyres - they do and not only to avoid accidents. Underinflated tyres suffer greatly accelerated tread wear and reduced tyre life. According to the American Trucking Association’s Technology and Maintenance Council (TMC), tyre-related costs are the largest maintenance expense for trucking fleet operators at 2 cents/mile or $2,375 for an annual 125,000 mile operation. Furthermore, according to their guidelines for tyre inflation pressure maintenance, 20% underinflation increases tread wear by 25% and reduces the casing life by 30% while a 40% underinflation halves the life of a tyre.

In response to these problems

The tyre pressure sensing arrangement can be integrated into existing mainline screening systems to identify vehicles with potential flat tyre violations so they can be directed to report for inspection. However, the sensor technology differs from the standard weigh-in-motion set up and instead of using load cells or piezo the sensor technology is based on the distortion of a ‘reflected’ signal caused by the size and weight of the tyre on the sensor. The accuracy is such that the system provides tyre detection rates of 99.5% and underinflation detection of 98.5%.

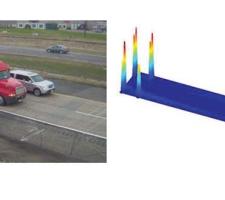

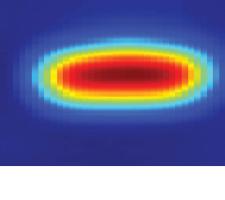

In operation, tyre footprint sensors produce a stream of data containing time, distance and pressure information for the numerous points along the length of the sensors which are buried in the surface of the road. The associated electronics perform continuous measurement sweeps along the length of the sensor at very high frequencies while the time difference between the tyre impacting each of the three sensors is used to determine the vehicle’s speed to within ±1.25%. When a tyre rolls over the sensor, a thin slice of the tyre contact patch is measured thousands of times per second. From this sequence of measurements, it is possible to construct a footprint of the pressure profile and location for each tyre on a vehicle as it rolls over the sensors.

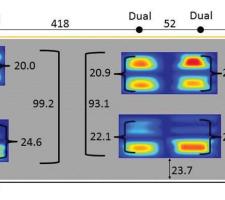

Standard width single, ‘super single’ and dual tyre configurations can be automatically determined from the trace of the tyre footprint and the system then differentiates between normal, overinflated, and underinflated tyres. For axles with a single tyre on each side of the vehicle, it is normal to assume that they would share the load equally. Based upon this, an underinflated tyre will have lower contact pressure but spread over a larger contact patch to support the given load – the tyre footprint sensor detects this difference and triggers an alert.

By coupling to automatic plate recognition potentially problematic vehicles can be identified and diverted for inspection.

Where axles have dual tyres, if one tyre is underinflated, then the other tyre of the dual will carry proportionately more of the load on that side of the vehicle. In such a case, the contact pressure will be significantly lower for the underinflated tyre and will again trigger an alert. If the data for an axle shows that the load on either side of the axle is different, an imbalanced lateral load can be identified. Imbalanced loads are caused by improper loading or load shifting making the vehicle more prone to loss of operator control.

Roy Czinku, IRD’s vice president of ITS Solutions & Maintenance Services, said: “Analysis of data from our test installation at the MnRoad research facility in Minnesota clearly showed numerous commercial vehicles with either underinflated tyres or the signal is very low indicating a completely flat tyre [below 50% of inflation]. This test installation, and other trial installations in Texas and Saskatchewan, are reliably detecting single and dual tyre axles with extremely accurate results at all vehicle speeds.”

In addition, as the position and footprint of every tyre on a vehicle can be determined, all types of vehicle configuration can be detected so the system provides enhanced vehicle classification. This includes two wheels (bicycles and motorcycles), three wheels (tricycles and motorcycles with unicycle trailers) as well as buses and oversized vehicles with nonstandard axle arrangements using tyres with pressures up to 13.8bar (200psi).

Also determined is the lateral position of the vehicle in a lane based on the position of the tyre contact patches relative to the location on the sensor. Where an installation has sensors installed in adjacent lanes, then vehicles traversing both lanes can also be identified.

By using the peak pressure and maximum tyre width measurements the system can provide an approximation of the load on a tyre. These measurements are independent of the vehicle speed, so the system can be used for monitoring at highway speed or in a depot. Even if the vehicle stops on the sensor the system will still provide a signal output while both speed and axle spacing can be measured using the time interval between activations of multiple sensors by successive tyres.

Asset Management

Infrastructure asset management is a vital function for agencies overseeing road systems. Calculations for roadway design and maintenance make use of traffic data inputs such as vehicle classification and load data to assist in making current and future plans. IRD’s new system can provide additional parameters to enhance vehicle classification algorithms and accuracy with information about the widths of vehicle tyres and the widths of each axle available to refine vehicle classifications. Precise, long-term data on vehicle lane position and the distribution of wheel paths along the width of the lane will provide information on expected wear patterns.

This information can provide augmented vehicle data for toll applications where the amount each vehicle is charged is based upon its type and number of axles and in some instances on vehicle weight. In-road traffic sensors verify the vehicle classes, thereby providing toll audit information. The tyre footprint information enables toll operators to implement additional vehicle classes into their toll fee schedule.

The system produces ‘per vehicle’ traffic data information that can provide a unique vehicle fingerprint to aid in the monitoring of heavy vehicles, including source/destination information associated with freight movements on public roadways.

For commercial vehicle operators these screening functions enable fleet managers to identify tyre pressure and load distribution issues during the normal course of vehicle operations. So in addition to addressing safety concerns, commercial vehicle fleet operators can benefit from reduced costs related to tyre maintenance.

Many authorities currently use a wide variety of sensors for traffic data collection, commercial vehicle enforcement, tolling, and traffic safety applications. The tyre sensor suite has the potential to perform these existing functions and to provide additional data sets that are currently unavailable with other technologies. This type of information is of great value for truck enforcement agencies, commercial vehicle fleet operators, road structural designers, road management agencies, toll operators, and many others in the transportation industry. And according to the company, tyre pressure monitoring and screening is only one of the many applications.