Huang Hua, an employee with Shanghai International Port Group (SIPG) - operator of one of the world's biggest and busiest ports - sits almost 100km away from the container port he works at, surrounded by a bank of computer screens. Terminal operating software, combined with IoT (internet of Things) devices and AI (artificial intelligence) provide him with the agility to maneuver containers on and off ships, while seated in an office rather than perched on a ship-to-shore (STS) crane. It is no longer a scene out of a science fiction movie, but indeed, it is made possible with the recent adoption of optical networking technology for centralised remote control in SIPG operations.

"From sitting on a crane for hours to being in the comfort of an air-conditioned office, the workplace experience has dramatically changed for me. Another benefit and a much-valued one is that, since I no longer need to commute to and from the port every day, I now have four extra hours to spend with my family."

Huang Hua's experience is the one that is also shared by 150 of his co-workers and their families. The transformation of SIPG is the world's first, marking a breakthrough in the operation of next-generation smart ports.

Jumpstarting digitisation of the maritime sector

Over the years, the maritime sector has been quite slow in adapting to changes and transforming its legacy processes. The recent bottlenecks resulting in queues of vessels waiting to enter ports in the US and Australia due to shortage of manpower, and the much publicised blockage of the Suez Canal causing an approximate loss of US$54 billion in global trade, highlighted the importance of digitalisation in the maritime and ports sector, especially in real-time issues monitoring and reporting, as well as reconfiguration of transportation routes.

With a majority of ports continuing to rely on manual, outdated practices such as whiteboards or spreadsheets to manage critical marine services such as towage, pilotage and launch boats, they are not prepared and unable to meet current needs. Such a situation is made worse with increased vertical integration between shipping and port services, and the need for improved cost-efficiency of operations and better communication.

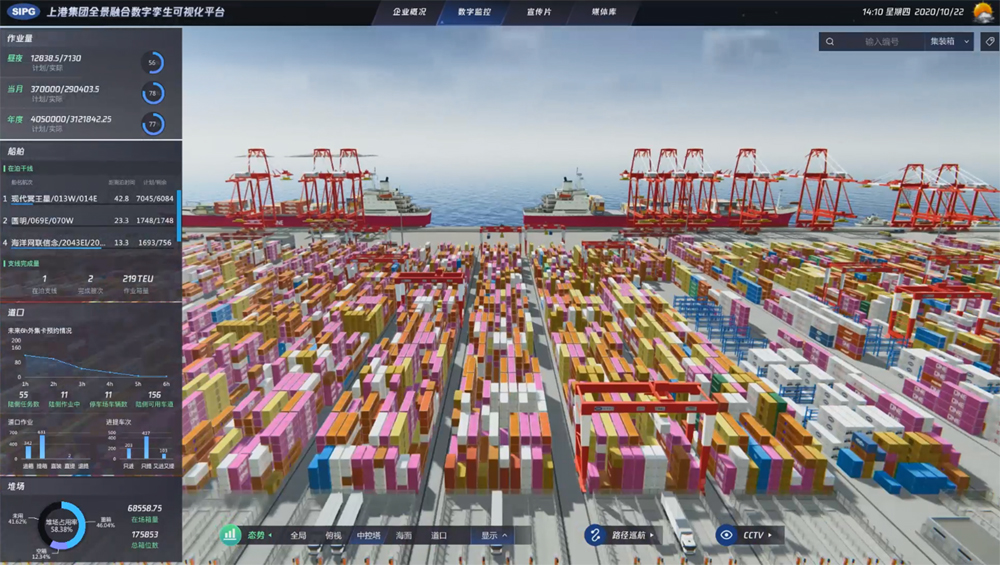

To stay abreast of the latest changes and challenges, in an ideal world, port operators and management staff need a 360-degree, real-time view of the physical port. Apart from the operational efficiencies port operators can enjoy, there are also significant benefits of safety and security. Such practice removes staff from unpredictable and dangerous circumstances, such as extreme weather conditions, allowing them to operate from a safe central location without the presence of moving containers, cranes and trucks. Fang Huaijing, vice president of SIPG explains, "We are building a future-proof port. In addition to enjoying improved emergency response and uninterrupted operations, the other key factor is the environmental benefit: the energy-saving attributes of the optical network makes the port greener."

The recent optical networking technology upgrade is helping SIPG better prepare for digital transformation. Given data from 11 ports is transmitted back to the remote control centre in real time, Fang believes a better utilisation of data is the key. "Prior to this, there was only storage and processing of data on the edge, resulting in loss of data sometimes. But now, we get hold of data in real time. Combined with AI and other technologies, the value of data in the future will unfold tremendous increase in productivity - providing SIPG with a core and distinct competitive edge," explains Fang.

The role of optical networking technology in digitisation of ports

Optical networking technology helps realise “fibre-to-the-machine” deployment, reconstructing the network architecture of large ports. Enhanced dynamic bandwidth allocation (eDBA) technology allows fixed bandwidth to carry industrial control services and flexible bandwidth to handle ultra-high definition (UHD) videos, implementing smoother remote quality control (QC) over conventional technologies. Moreover, the optical networking technology simplifies network layers and centrally carries machine and campus networks, with the visualised network management system (NMS) reducing the O&M workload by 60%.

Second, it helps to connect the backbone WAN of large ports. An all-optical data highway is built between ports, achieving outstanding transmission capabilities with Tbit/s ultra-large capacity, μs-level low latency, and zero jitter over distances exceeding 100km. Such transmission creates infinite possibilities for the application of new technologies — such as edge computing, intelligent analysis, and machine learning. More importantly it helps ports embrace the potential of developing Port Intelligent Twins.

Port Intelligent Twins

Huawei's Port Intelligent Twins is based on a vision to create an intelligent twin of a physical port that requires no manual intervention and operates logically, scientifically and optimally. It forms the overarching strategic framework under which solutions such as centralised remote control of port operations are implemented.

The term 'Digital Twin' was first proposed by Professor Michael Grieves of the University of Michigan in a speech on 'Conceptual Ideal for product lifecycle management (PLM)'. By forming a port development model combining virtual reality (VR) and twin interaction, the whole life cycle management of the port can be mapped out. Subsequently, intelligent logistics scheduling can be built, so as to promote cost reduction of the whole logistics chain.

SIPG is not the first Port Intelligent Twins project that Huawei has worked on. The company has been working with Tianjin Port since June 2020 on the execution of this vision and is looking at four intelligent aspects: applications, a hub, connectivity and interactions.

Wang Guoyu, President of the Global Transportation Business Unit of Huawei Enterprise BG, explains, "Huawei develops the 'Port Intelligent Twins' across all processes, service architectures, and lifecycles of smart ports based on application innovation and ecosystem aggregation. We use digital technologies such as cloud, and intelligent vision to deeply integrate with service scenarios of traditional industries, and leverage new ICT to improve intelligence and computing power. In doing so, we enable industry digitalisation and upgrades, creating new productivity for conventional labour-intensive enterprises and driving digital economic development."

Such projects are not one-time implementation feats but more phased approaches that incorporate various scenario-building modules. The end result will help ports support better labour structure, ensure higher efficiency and lower costs, and enable safer port operations. Some of these benefits are already in view at the Tianjin Port where shortening the container crane work plan from two hours to mere minutes has improved the work efficiency by more than 10% and reduced overall operation costs by 10%. Thanks to proactive intelligent security protection, efficiency of identifying security incidents is expected to increase by 30%.

On the lines of the successful digital transformation practices underway at Tianjin, Huawei has joined hands with SIPG to establish a Port Intelligent Twins innovation centre. Aimed at building a world-class smart port, the companies will accelerate the overall improvements of SIPG's intelligence, efficiency, and experience.

For more details about smart transportation in a smarter world, please visit here.

Sponsored content produced in association with Huawei

Watch our video below: Port operators enjoy improved emergency response and uninterrupted operations under a 360-degree, real time view of the physical port