Seattle’s downtown waterfront will be redeveloped once the SR99 tunnel is open and the last northern section of the Alaskan Way Viaduct demolished

Earthquake sensors, automatic barriers and real time monitoring systems are all part of a scheme to make a major Seattle traffic artery safer, by taking it underground. Huw Williams reports.

Seattle’s metropolitan area of 3.5 million people, like much of the western seaboard of the United States, lies in an earthquake zone. In Seattle’s case, the city and its hinterland sit atop a complex network of interrelated active geological faults capable of severe seismic activity and posing complex considerations for communication and transportation networks.State Route 99 is a major arterial highway that carries 20-25% of all north-south traffic through Seattle. For about three kilometres, as it passes through the heart of the city, the road is raised, running on a reinforced concrete, double-decked bridge known as the Alaskan Way Viaduct.

The 1950s structure was already showing its age with problems of exposed rebar, crumbling concrete and weakening column connections when in 2001, the area was hit by the Nisqually earthquake. The tremor recorded a magnitude of 6.8 and caused $2bn worth of damage regionally. On the casualty list was the SR99 viaduct. It was repaired, but subsequent regular monitoring revealed settlement, structural movements and cracking.

Essential works

Deputy program administrator for“The viaduct is in extremely poor shape. It is deteriorating under normal traffic loads and it is extremely vulnerable in a seismic event. It has been through two of them and it won’t take a third. Models have shown that there is a one in 10 chance that in the next 10 years there will be an event of sufficient magnitude to take the structure down. We don’t like those odds.”

The southern section was demolished in 2011; as it passed through an industrial area there was the luxury of space – surface streets and two parallel bridges have taken its traffic flow. The first bridge is already open and the second is due to be completed by 2013. Yet how to replace the northern section posed a more complex problem as it passed along the waterfront of the downtown district: the business and commercial heart of Seattle.

Significant undertaking

Proposals for a cut-and-cover tunnel and a new raised viaduct were both rejected and a decision eventually reached to construct a bored tunnel. One reason a tunnel was chosen rather than building a new viaduct is because, as design director Dan Dixon explains, tunnels are safer during an earthquake than surface structures.“Constructions in the ground move with the ground, whereas above ground the mass of the structure can start moving in the opposite direction imposing magnitudes of greater forces on the structure.“

A bored tunnel was chosen as a cut-and-cover option was deemed too disruptive in such a key urban area. With the dig taking place up to 60m underground, the impact at the surface can hopefully be minimised. Even so, construction of a tunnel under some of Seattle’s most important real estate is a significant undertaking, one that Matt Preedy is well aware of.

“It’s not like we are trying to do the world’s largest bored tunnel under a farm field where if you get some sort of settlement of the ground it really doesn’t matter. Here every bit of ground settlement matters. ”The solution is technology: a diverse and robust state-of-the-art monitoring system.

“We are installing a vast array of benchmarks throughout downtown; some surface benchmarks others drilled a couple of hundred feet down. There are a variety of cyclopse arrays that are going to be all interconnected along the tunnel route and these remote monitoring stations will be able to look at potential building or ground movement as the tunnel progresses underneath downtown. We have a satellite monitoring system as well looking at things from overhead.”

Seismic safety

The bored tunnel option also offered the opportunity to minimise disruption to traffic flows by keeping the existing viaduct open until the tunnel is complete. This doesn’t mean safety issues plaguing the viaduct have been ignored; rather, an innovative application of technology has artificially extended its safe operating lifespan.A series of independently powered earthquake sensors have been sunk into the ground around the city and its surrounding area.

They are linked via their own communications network to nine barriers that automatically drop to block traffic from entering the slipways and stop traffic on the viaduct within minutes of a tremor being detected. Previously, closing the viaduct was done using maintenance crews driving along and setting up roadblocks. This could take up to two hours from the initial earthquake warning.

“There have been minor earthquakes and we know the sensors are working. We have real-time evidence that the monitors are picking up things accurately and are calibrated right, so we are very confident that if it is needed, it will operate,” says Preedy.

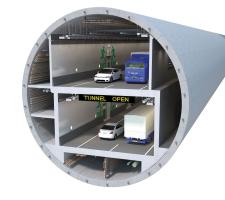

With the new earthquake safety measures on the viaduct in place, work has begun on the replacement tunnel. This will be the world’s largest soft-ground tunnel ever constructed with a tunnel-boring machine 57.5 ft (17.5m) in diameter. Two TBM launch pits at either end of the 9,300ft (2.8km) tunnel drive have already been sunk and completion is scheduled for 2015.

The total length of the tunnel will be 11,940ft (3.6km) between its two portals, for which substantial work is required, involving construction of cut and cover tunnel sections and a series of reinforced concrete ramps on the approaches to get northbound traffic beneath southbound lanes for the tunnel’s double deck internal structure.

Tunnel management

Tunnels may well be inherently safer during an earthquake than many surface structures; however, they have their own associated safety and management challenges; air quality, vehicle breakdown, collision, fire. All need to be addressed and as Dan Dixon explains, cutting edge technology has been combined with expert knowledge and detailed risk assessment to provide as safe a solution as possible.“There are mini video cameras, there’s an escape system, a rebroadcast system so emergency response providers can communicate with people in the tunnel. The life safety systems have been developed with the fire marshal in the city of Seattle so that the ways that they are monitored and deployed are coordinated with them. There are operations buildings at both ends of the tunnel, if one goes down the other can continue functioning.”

In addition to the video cameras, all vehicles will be logged using loop technology and a VMS system will provide drivers with real-time traffic management and safety information. So if a breakdown or collision happens, the incident detection system allows the 24-hour operations team to view and act, conveying messages to drivers via overhead electronic signage and initiating the necessary emergency response.

Tolling policy

However, one aspect of the completed tunnel’s operation has yet to be finalised: the tolling policy. No more than the $400M of the tunnel project’s $2bn total cost is permitted to come from toll revenues. The remainder is being funded by Washington State gas tax, local and federal sources.The tolling technology is likely to integrate with that introduced elsewhere in Seattle. Electronic readers and cameras on overhead gantries will record each vehicle movement and automatically charge each driver’s account, but the exact fees are yet to be decided. Income targets need to be met, but if drivers deem the tolls too expensive they will find alternative routes, with potentially catastrophic impact on the fiscal viability of the viaduct replacement project as a whole and on traffic flows throughout Seattle. Over the course of the next few months a team of business, technical and political experts is looking at exactly what fee to set to make the tunnel work, and pay.

<%$Linker: